Depending on the design, the

pistons are driven by a wobble plate or a swash plate. In a wobble plate

compressor, the pistons are connected to the plate with short push rods.

An angled yoke on the driveshaft causes the plate to wobble when the

shaft rotates, driving the pistons back and forth in their bores.

In a swash plate compressor,

the plate itself rotates with the driveshaft. A bearing in the bottom of

each piston “clamps” around the edge and rides on either face of the swash

plate.

The plate is set at an angle

to the shaft, so as it rotates, the pistons are forced back and forth in

their bores.

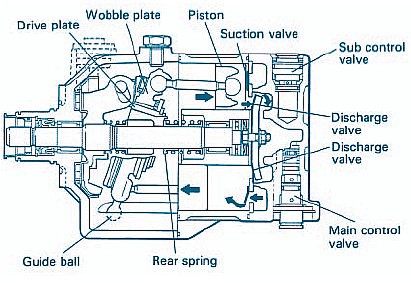

The angle of the wobble

plate or the swash plate determines the length of the piston stroke. In a

variable displacement compressor, that angle can be changed, which changes

the length of the pistons’

stroke and, therefore, the

amount of refrigerant displaced on each stroke. The angle is adjusted

using springs and linkage that move lengthwise along the driveshaft, and

it’s controlled with refrigerant pressure in the compressor housing. When

housing pressure is increased, the pressure exerted on the back side of the pistons

keeps them “higher” in their bores and closer to the cylinder head. This

shortens the stroke, reducing displacement.

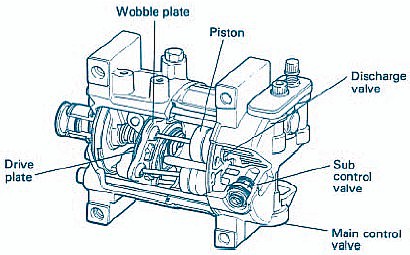

VARIABLE DISPLACEMENT

A/C COMPRESSOR

This electric control

valve (left) includes the pressure sensor in the valve assembly, but

the sensor could be mounted anywhere in the system. The Delphi

compressor (right) uses an adjustable swash plate to change piston

displacement.

When housing pressure is

reduced, a spring pushes the adjusting linkage away from the cylinder

head, increasing plate angle and lengthening the piston

stroke to increase

displacement. Housing pressure is adjusted using a control valve with

ports and passages that connect it to the suction (low-side) and discharge

(high-side) chambers of the compressor head. Two different types of

control valves are used. The traditional mechanical

valve has a precision

pressure sensitive diaphragm that senses low side pressure. When the cabin

temperature is warm, evaporator temperature increases, which increases low

side pressure. This pushes on the diaphragm, opening a port that vents a

little bit of housing pressure to the suction side. Reducing housing

pressure increases piston stroke, which increases refrigerant flow volume

through the system. As evaporator temperature decreases, so does low side

pressure. The diaphragm “rebounds” to close the low-side vent port and at

the same time open a port that admits high-side pressure into the housing.

This reduces piston stroke and, therefore, refrigerant flow volume.

Remember, changing flow volume doesn’t necessarily change pressure.

Around 2001, DENSO was first to replace the diaphragm valve with a

solenoid valve and add temperature and pressure sensors in the refrigerant

system. This allows a computer to control the valve and adjust compressor

displacement to control evaporator temperature, rather than using

evaporator

temperature to control

displacement. Today almost all manufacturers offer electronically

controlled variable displacement compressors, and some applications have

no clutch, meaning the compressor runs whenever the engine is running.

Most vehicles already operate the compressor any time the windshield

defogger is turned on, even in winter. The electronic displacement control

valve makes it easier to run the compressor continuously because

displacement can be reduced closer to zero than with a mechanical valve.

Continuous operation keeps seals lubricated, minimizes oil pooling and prevents other kinds of

damage that result from long periods of inactivity.

6-CA COMPRESSOR

A cut-away of a Nippondenso 6-CA

compressor. When housing pressure is low, the rear spring increases

drive plate/wobble plate angle, thus increasing displacement.

Also, with the A/C system

controlled according to cabin temperature demand as opposed to evaporator

temperature demand, the need to reheat air that’s been cooled below the

requested temperature is eliminated. Ultimately the electronically

controlled variable displacement compressor puts less load on the engine,

improving fuel economy by as much as one-half mile per gallon. And of

course, the driver will never feel the A/C clutch cycling or the idle

speed surge that sometimes accompanies it.

The mechanical control valve

is inexpensive and reliable, but it doesn’t provide the same control as

the electronic valve. Eventually most A/C systems will use an

electronically controlled variable displacement compressor.